727s proved to be very efficient airplanes for short to medium range flights across the world. Their design culminated from a compromise among requirements of United Airlines, American Airlines and Eastern Airlines. They all required an aircraft for operations on smaller airports with shorter runways and fewer passengers, but their engine requirements differed. American airlines wanted a twin engine for fuel efficiency as they were already operating 707s powered by four engines, United airlines wanted four engines for its high altitude hub operations in Denver and Eastern airlines wanted a third engine for over water operations. Boeing would eventually come up with a Trijet, T-tail, narrow body and clean wings (no engines mounted on wings) design.

The first 727-100 entered service with Eastern Airlines on February 1, 1964. Once in service these classic beauties proved to be so dependable that they became workhorses for many commercial airlines both in passenger and cargo operations. Their popularity further extended to the private business and VIP charter business where they also thrived and even managed to serve as private jets to some of the richest people in the world including the billionaire former US president Donald Trump.

With a total of 1832 produced, very few are currently in active service around the world today, most of them operating as freighters. As of may 2013 there were only thirteen 727s in operation around the world. Twelve of these were the stretched 727-200s while only one was a 727-100. The last Boeing 727 scheduled passenger flight took place on 13 January 2019 by Iran Aseman airline between Zahedan and Tehran.

As of August 2021, there are only five 727s operating from Nairobi’s Jomo Kenyatta International Airport, owned by two local airlines. Four of the five are serving as freighters and one is a VIP charter.

The most unusual features of the 727s include:

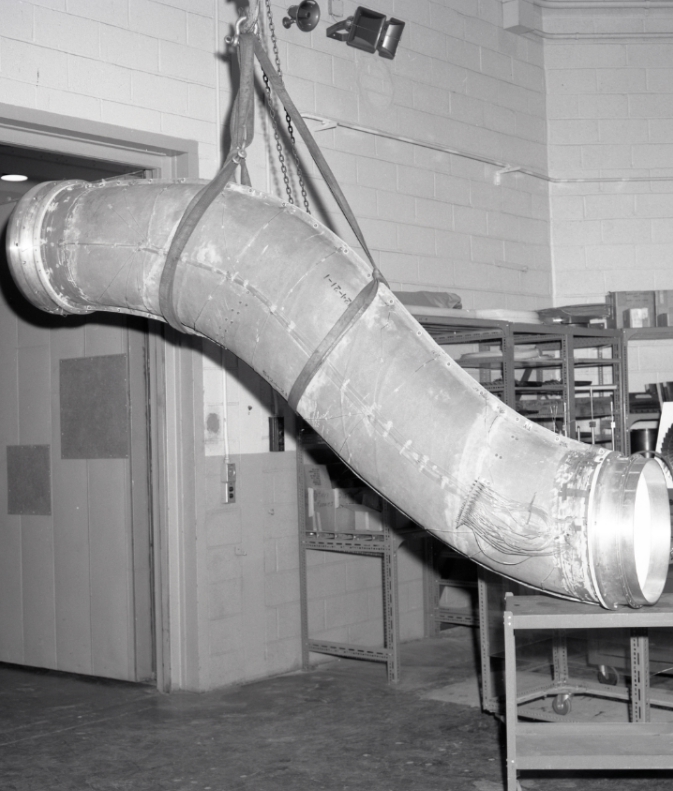

1. An S-Duct (serpentine inlet) air intake duct for #2 engine

This was the most iconic feature of the Boeing 727s. It was not however exclusive to them, as they shared this air intake design with some other aircrafts.

the S-duct design on 727s was developed for the center mounted engines to help lower the engines for easier access during maintenance. To appreciate this idea, check out the position of the center engine on MD-11s and DC-10s

2. AUXILIARY POWER UNIT (APU) MOUNTED IN THE WHEEL WELL

Position of the mid engine and the rear airstair eliminated the possibility of intalling the APU in the aft section of the aircraft. The result of this was to mount it in a hole through the keel beam web separating the left and right wheel wells.

To offer fire protection, the APU was enclosed in a stainless steel metal casing. This location however, imposed some operational limitations as the APU could not run with the main landing gears retracted.

3.Nose wheel brake

Not a common feature in aircraft design but 727s had them. The idea arose from the requirement to operate on short runways, resulting in the need to effectively reduce landing runs.

The brakes were so effective when used they reduced braking distance by up to 150 meters. They were however optional, and therefore operators had the liberty to deactivate them based on their operational requirements.

4. Cooper vane

Dan Cooper, was an Alias used by an unidentified man to purchase a plane ticket and board a plane which he later hijacked on November 24, 1971. The plane was a passenger 727 operated by North West Orient airlines on a flight between Portland and Seattle. The flight made a stop at Seattle Tacoma airport to collect a ransom worth $200, 000 (now valued at $1.29 million) and four parachutes. While airborne again over southwest Washington, Cooper opened the aft entry door in the rear pressure bulkhead then he opened the aft airstair and leaped off the plane. His fate remained unknown and his case turned out to be the only unsolved air piracy in the history of commercial aviation. However, while covering this report a miscommunication arose among media houses which changed the name to D. B. Cooper.

The story of D. B. Cooper led to the development of a small vane intended to lock the aft airstair in flight and make it impossible to be opened in flight. The vane is normally spring loaded in a position to allow the airstair to open while on ground, but once in flight, aerodynamic force created by air ramming against it turns it against the spring tension so that it is now positioned in the way of the ramp.

5. Noise

Development of jet engines revolutionized aviation a great deal by meeting the demand for power and speed. The price to pay for these, however, was noise. Power and noise had a direct proportion relationship. The higher the power output the louder the engine. Later on, the demand for fuel efficient and environmental friendly engines arose and by-pass engines were developed. Boeing 727s were built in the era of low by-pass engines and were fitted with three JT8D-17 low by-pass engines manufactured by Pratt and Whitney. With most of the air going through the combustion chamber, low by-pass engines were loud and 727s were ranked among the noisiest commercial jetliners.

The U.S Noise control act of 1972 act categorized 727s as stage 2 aircrafts and called for the development of quieter stage 3 engines. This was later achieved by increasing the engine by-pass ratio, a feature which proved to be very effective for its intended purpose. For 727s, Boeing determined that the noise could be reduced by replacing the two side mounted engines with JT8D-200 engines. These had a higher by-pass ratio and hence were quieter and more fuel efficient than their predecessors the JT8D-1 to 17. However, the structural modifications required to install the proposed engines were somewhat prohibitive, and for this reason, hush kits were later developed to be fitted to the engines to help reduce the noise.

Re-engining

In the late 80s, Valsan Partners limited introduced two programs to upgrade 727-200 models. First was a partial re-engining program which replaced the side mounted engines with the much larger and quieter JT8D-217C/219 and fitted the center engine with a hush kit. The second upgrade was a pair of aftermarket winglets which were later marketed by Quiet wing corp. These also reduced noise at lower speeds and improved fuel efficiency. The 727s incorporating the valsan re-engining modification were renamed Super 727s.

Rolls Royce too developed re-engining programs both for 727-100 and 200 but only managed complete re-engining of 727-100s. The three JT8D engines on the -100s were replaced with the more powerful and quieter Rolls Royce Tay 651 engines. All the re-engined 727-100s were operating for United Parcel Service (UPS) and were named Quiet Freighter (727-100QF). With the new engines fitted, the operator managed to record a reduction in fuel cost of 18%. After this, Rolls Royce realized potential market for re-engining, and once again they embarked on a second program to re-engine 727-200s with larger and also quieter Tay 670, but before they could get a launch customer, the program stopped due to political considerations within the european community.