Something has come up and you suddenly need to catch a flight. You purchase a plane ticket and pick a window seat. After boarding the plane you settle into your sit, ready for the exciting flight. However, once you take a glance around the cabin and then outside the window your excitement turns to disappointment as you are greeted with views of some sort of shiny tape on some parts of the exterior surface of the plane. “Is this safe, will that tape hold the broken parts together for the entire journey?, how old is this plane?, is this the best the airline can do to maintain their planes?, I think they could have done better… do they even care about their reputation?” Out of frustration, you decide to take a photo so you can share the mediocrity on social media or even send a feedback to the airline”.

A Boeing 787 wing with patches of speedtape

Flying is still considered prestigious even at the present age. The price of an airline ticket is also still high and therefore aviation passengers usually have high expectations of value for money in terms of comfort and safety. Sights of patches of tape on a plane would trigger concerns about quality of maintenance and whether the plane is safe for flight. However despite several standoffs between passengers and some airlines on social media over this same issue, it is still very common to find the shinny tape on planes.

Not too long ago a photo of an airplane operated by Kenya Airways (KQ) was trending on social media, over what was being described as a patch of ‘sellotape’ repair. The responses which accompanied the post contained hostile comments towards the airline. KQ is not the only airline which has found itself on the receiving end of this kind of accusation. Other prominent airlines as well, including Qantas, Spirit airlines, Easyjet, United airlines, Air New Zealand and many more, have also had similar claims hurled towards them.

So what is this mysterious sellotape?

The so called sellotape is known by engineers as speedtape. It is a pressure sensitive tape made of an acrylic adhesive backed with a foil of pure alumunium. The tape is approved for use in quite a number of applications. Among them is to temporarily protect or preserve the structural integrity of aircraft skins, and to accomplish temporary or non-critical repairs on airplanes. Its shinny-metallic appearance makes it easy to be mistaken for the more common duct tape. Once installed, the tape is usually able to remain attached to the exterior surfaces of an airplane at high cruising speeds; and hence the name speedtape.

Speedtape almost halfway used

Speedtape is suitable for use on airplanes because it is, waterproof, resistant to many solvents, flame resistant to a reasonable degree, is able to reflect heat and UV rays and it is capable of expanding and contracting reasonably well with varying temperatures. However, in order to make it understood how this controversial tape protects airplane skins then it is also inevitable to detail what makes up the skins and the damaging elements which they must be protected from.

An unpainted section of an airplane during routine maintenance, showing skin built with carbon fiber

Modern airplane skins are critical structural members. They are usually built using aluminium alloys, composites, or titanium alloy (in areas subjected to high temperatures). These materials are known for their excellent anti-corrosion and high strength to weight ratio properties. However, the use of composites for airplane skins is becoming increasingly popular on newer planes.

Composites are non-metallic materials and so they do not corrode. The most commonly used type of composite for the construction of newer airplane skins is carbon fiber laminate. It is usually made by joining several layers of carbon fiber cloth together using a resin (or what a layman would call glue). The process is normally done under specific temperature and pressure conditions suitable for the resin to cure; and other contaminants, especially moisture to be eliminated. The final product is nearly 1.7 times stronger than aluminium.

A close-up view of a bare carbon fiber material

On the other hand, aluminium alloys usually have a thin layer of a chemically stable oxide which protects the metal beneath from further corrosion or attacks by chemical agents.

UV radiation

UV is a form of electromagnetic radiation which is naturally present in sunlight. It can also be generated by electric arcs, special lights such as black light, tanning lamps and mercury vapor, and a phenomenon called cherenkov radiation. Lightning strikes caused by electric arcs do generate considerable amounts of UV, but the sun is the main natural source of harmful UV radiation.

Despite being highly resistant to corrosion aluminium alloys can corrode, and composites can undergo accelerated deterioration. UV radiation causes the chemical bonds of the cured resin in composites to break, leading to gradual loss of the mechanical properties of the material and consequently compromised structural integrity. Degradation on composites can be indicated by discoloration or yellowing. Besides exposure to UV radiation, degradation of composites can also be caused by exposure to harsh chemicals.

Similarly, when exposed to UV radiation, aluminium undergoes dramatic photocorrosion in the presence of moisture, resulting in visible corrosion pits on the exposed surface.

back to speedtape

A small section of an airplane wing with peeled paint, exposing the composite material underneath

To prevent direct exposure of airplane skin structural materials from damaging environmental elements, including UV, a special kind of paint is usually applied onto their surfaces. The paints do contain elements that are resistant to some harsh chemicals and are also able to block UV radiation.

However, if paint work is done poorly, or the airplane encounters severe environmental conditions or contact between the paint and a harmful chemical occurs; then the paint peels off, leaving the skin underneath bare and vulnerable to the harmful elements. In some other cases selection of top finish paint might have been made poorly such that a type of paint which is less tolerance to UV is used, and hence it just peels off on exposure to sunlight. Airplane skins may also be exposed due to scratches which are usually inflicted during ground operations from contact with servicing vehicles, foreign objects, or while undergoing maintenance.

Aircraft maintenance inspections and any other tasks are normally carried out in accordance with guidance information contained within aircraft maintenance manuals. During routine maintenance inspections, existing defects are usually identified and reference made to the maintenance manuals for related guidance rectification tasks. Some defects are classified according to the effects they would have on the normal operation or safety of airplanes. Small patches of peeled paint in most cases are considered minor defects and corrective actions to be undertaken are usually detailed within the manuals. Other common types of minor defects that are regularly found on airplanes include loose or missing fasteners, loose or broken latches or handles, peeled or cracked sealants and many others. In most cases, loose or missing fasteners and broken latches or handles are normally caused by severe vibrations, lightning strikes or flight into abnormal weather conditions that may impose excessive loads on the airplane structure. Cracked or peeled sealants can be caused by ageing, poor sealant mixing or application techniques or erosion due to impact with high velocity particles in the air.

High velocity airflow in flight would cause a small section of peeled paint to grow bigger exposing more areas to the environment; whereas vibrations would cause loose fasteners to loosen further and even erode the fastener holes. Loose latches or handles would also loosen further and consequently break away from the plane. Rectifying minor defects early enough prevents them from worsening or causing secondary damage to the plane.

Permanent corrective actions would be to repaint sections with peeled paint, replace missing or loose fasteners, or repair dents and scratches. However, if there is immediate demand for the plane to fly and pulling it out of service would cause passengers to miss a flight or the airline to lose significant revenue; the airplane’s repair manual provides for temporary repairs to be carried out for a specified duration or until there is sufficient ground time for permanent repair to be done. One of these temporary repairs is application of speedtape to cover small patches of peeled paint or covering a fastener hole or peeled sealant to prevent moisture ingress.

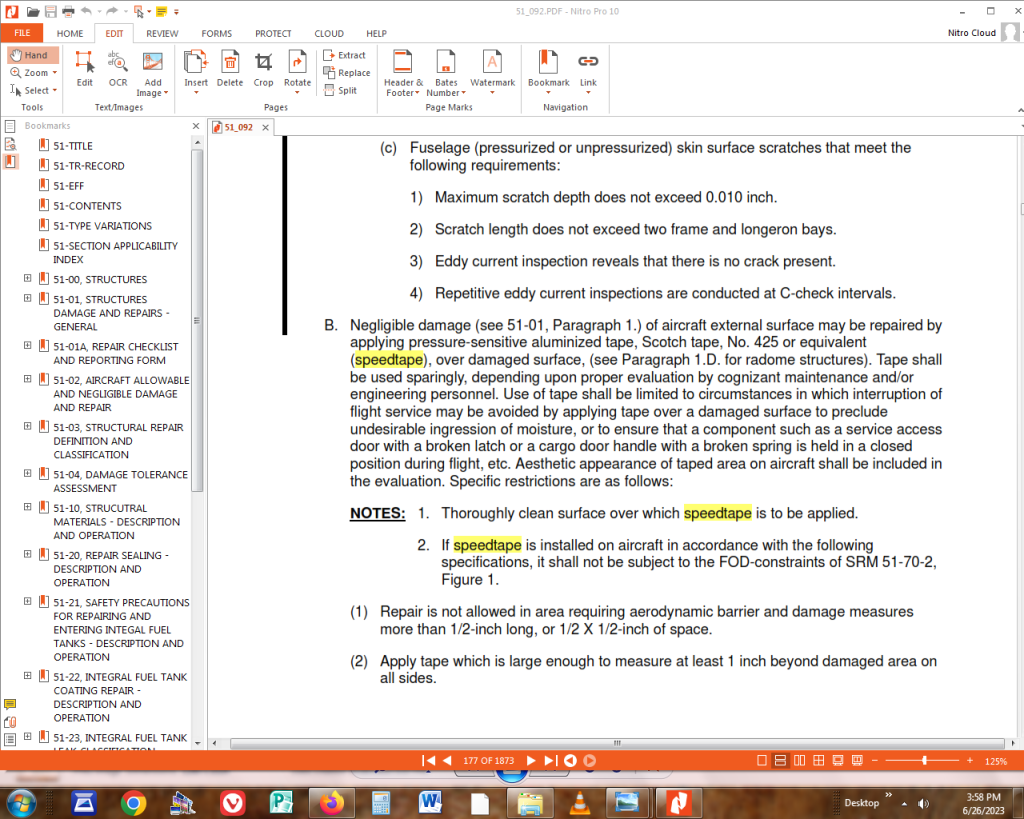

An excerpt from an actual aircraft Structural Repair Manual with instructions to apply speed tape to the external surface of an aircraft

It is therefore not a lazy engineer’s decision or shoddy maintenance practices by airlines to patch an airplane with speedtape; but it is a time saving temporary repair which is called for by the plane manufacturers for certain minor defects after careful analysis of the damaged area has been done. Following application of speedtape, the patched area is usually monitored consistently just to ascertain effectivity of the repair.

Peeling of paint has become particularly common on planes built with carbon fiber. This type of composite material would suffer severe damage when exposed to high levels of UV radiation over extended periods. More often the peelings do occur over short intervals that it may not be economically reasonable to pull out the plane from service for repainting to be done. This is why you will most likely find some patches of a shinny tape over the wings of the dreamliner next time you board one. Airbus has had its fair share of paint problems; which went as far as planes being returned for repainting, and cancellation of airplane orders by Qatar Airways. On the contrary, Boeing troubles didn’t reach this far, and neither may they get any worse. In mid November 2022, Boeing applied for certification to alter composition of paint on dreamliners to make it more tolerant to UV. Sights of shinny tape may therefore be a thing of the past on dreamliners in the near future.

Well, the next time you get on a plane and see shinny tape patched on its wing, engine or other parts of its exterior surface don’t let it bother you or ruin your travel mood. Just sit back, relax and enjoy your flight..